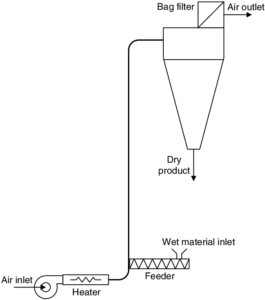

Pneumatic conveyor dryers often referred to as flash dryers, consist of a duct carrying gas at high velocity.

The solids can be fed by various methods: screw feeders, venturi sections, high-speed grinders, and dispersion mills.

Selecting the correct feeder to properly disperse the solids in the gas is critical for efficient drying.1

A Fluid Energy ThermaJet style ring dryer is a variant of the flash or pneumatic dryer. An advantage of our ring style pneumatic dryer is a short retention time.

In a conventional, straight tube flash dryer, the residence time is basically fixed for all particle sizes of material, even though larger particles may take longer to dry.

This limits the application to materials in which the drying mechanism is not diffusion-controlled (i.e. constant rate drying, not “falling rate” drying) and where a range of moisture within the final product is acceptable.

Advantages of the Flash Dryer

A ring configuration offers two advantages over the straight tube. First, residence time varies with the particle size of the material.

Finer particles, which dry quickly, will be carried out with the airflow sooner, while larger particles, which dry more slowly, will make multiple cycles in the outer part of the dryer loop due to their heavier weight and the centrifugal forces created by the airflow within the ring.

The larger particles will now have a longer residence time for drying.

Second, although the dryer typically operates at lower pressures than a loop or torus jet mill, cycling through the ring can grind the material while drying. Even if grinding doesn’t occur, the internal forces are strong enough to break apart (de-agglomerate) wet cakes and clumps. This unit operation can control product particle size and moisture in the same process step.

Alumina Slurry Drying

A Fluid Energy Model 4 ThermaJet was built to dry alumina slurry from an initial moisture content of 80% to a final level of 0.2%.

The dryer includes a rotary valve feed inlet, replaceable abrasion-resistant liners, and a high-temperature manifold with inlet expansion joints.

Additional system components include a process blower, direct-fired natural gas heater, cyclone, baghouse and exhaust fan.

A slurry pump, screw conveyor, and continuous mixer were added to handle slurry feed. It recycles a percentage of dry product through a paddle mixer, increasing the solid content of the slurry to form a filter cake-like consistency for feeding through the inlet rotary valve.

Agricultural Chemical Drying

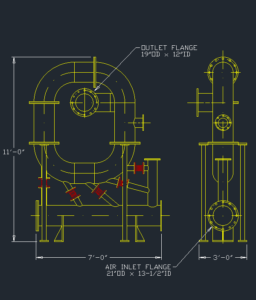

A Fluid Energy Model 14 ThermaJet, shown in the drawing at the left, was designed in a horizontal configuration in order to meet a customer’s space requirements.

The unit dries a heat-sensitive agricultural product from an initial moisture content of 10% to a final level of 0.2%.

Since some solvent is driven off in the drying process, the ThermaJet system operates with a closed-loop, nitrogen recycling package using a steam coil heat exchanger.

A condenser has been included in the system to remove solvent and water vapor from the process stream prior to recycling.

Drying & Calcining of Iron Oxide

The Model 10 ThermaJet, shown in the picture to the right, dries yellow oxide from an initial moisture content of 40% to 10% bound moisture.

The Model 10 was combined with a Model 12 to provide calcination of the dried oxide. The system begins with a yellow iron oxide wet cake and produces a dry, fine red iron oxide pigment.

Drying temperatures run from an inlet of 800ºF (430ºC) to an outlet of 210ºF (99ºC). Calcining temperatures include an inlet of 900ºF (480ºC) and an outlet of 650ºF (340ºC)

The calcining portion of the system includes an evaporative cooler located after a cyclone to cool down the process stream before entering the baghouse.

Silicate Drying

The Model 26 ThermaJet was designed to process a silicate filter cake from an initial moisture content of 40% down to 10% bound moisture. The Model 26 includes a separate hot air manifold to operate at 1200ºF (650ºC) with inlet nozzle expansion joints.

This unit also accepts direct feed from a volumetric screw feeder. Additional system components include a process blower, a direct-fired natural gas heater, and a reverse pulse collector & exhaust fan with actuated damper. Process controls were integrated into an existing PC-based control system.

These case studies summarize a few applications of the ThermaJet dryer. Additional applications can be found here on the ThermaJet webpage. The case studies demonstrate the versatility and capability of flash drying systems:

- Capable of processing heat-sensitive and volatile materials. Able to process materials including wet powders, slurries, sludges, and filter cakes.

- Flexible feed capacities for laboratory, pilot, and full-scale production with feed rates ranging from 10 to 100,000 pounds per hour.

- Produces dry, discrete, deagglomerated products from raw feeds containing up to 95% moisture, often eliminating the need for additional grinding.

- Incorporate a broad range of operating temperatures and pressures for specific drying applications.

- Allows for calcining operations with immediate response time and instantaneous changes in product characteristics.

- Capable of integration with virtually any air heating system and offered with a variety of control options for customized drying applications.

- Able to operate continuously with superior reliability and minimal maintenance.

References:

1. Czeslaw Strumillo and Tadeusz Kudra, Drying: Principles, Applications, and Design, Gordon and Breach Science Publishers, 1986.

2. Irene Borde and Avi Levy, 16-Pneumatic and Flash Drying, Handbook of Industrial Drying, Editor Arun S. Mujumdar.