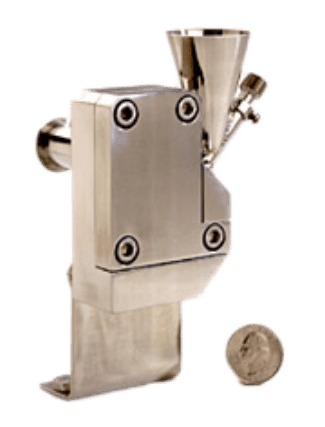

Fluid Energy offers a comprehensive range of fully scalable research and development grinding systems perfectly suited for laboratory applications. The self-contained portable tray systems are designed to process batch sizes ranging from 1g to several kilos while maintaining yields in excess of 95 percent. Available on a purchase or rental basis, these mills produce a fine, narrow particle size distribution, consumes minimal amounts of energy and is easy to feed with a wide variety of materials.

The system includes a mill, a feeder with controls and all piping and instrumentation necessary for operation. All components are constructed of type 316 stainless steel with a pharmaceutical polish. Collection options include filter sleeves, small sample collectors, cyclones or tabletop HEPA filters.

JET-O-MIZER technology injects air, steam or inert gas through specially designed nozzles, creating sonic velocities. Solid particles of raw feed are injected into the turbulent grinding stream. The resulting high-velocity collisions provide effective pulverization of the raw feed into fine particles from 0.5 – 45 µm.

Unlike many other laboratory scale grinding systems, the results achieved using a JET-O-MIZER system are fully scalable to larger pilot or production scale mills.